Stylus alignment is a critical aspect of turntable setup that significantly affects both audio fidelity and vinyl longevity. Precise alignment ensures that the stylus reads the grooves in your records accurately, extracting every nuanced detail etched within. An accurately aligned stylus will follow the grooves with minimal friction and distortion, channeling the purest sound from your vinyl collection to your speakers.

Neglecting this step can lead to audio imperfections and potentially damage your precious records over time. Suboptimal tracking not only diminishes the listening experience by introducing errors in sound reproduction but also increases the wear on both the record and the stylus itself.

Proper alignment will preserve the integrity of your records and optimize the lifespan of your turntable’s components.

Table of Contents

Fundamentals of Stylus Alignment

Proper stylus alignment on your turntable is critical for achieving high-fidelity audio playback and preserving your vinyl records. Misalignment can lead to audio distortion and premature record wear.

Anatomy of a Stylus

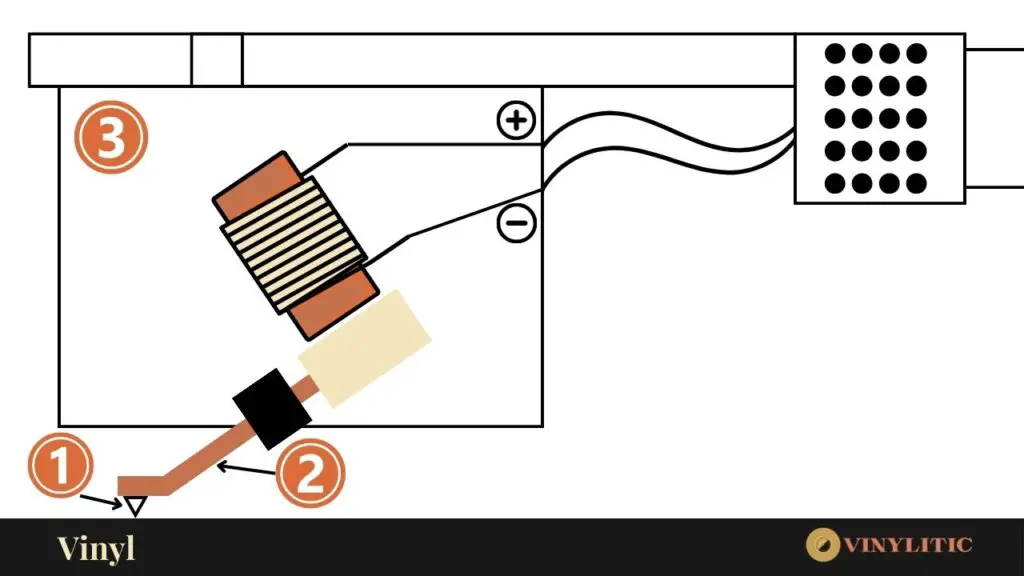

Your stylus, or needle, is the small tip that reads the grooves of your vinyl record. It is typically made of diamond or another hard material and is mounted to a cantilever. Key components include:

A stylus must be aligned correctly in both the vertical and horizontal planes to track the record grooves accurately.

Importance of Alignment

Alignment is paramount for two main reasons:

- Sound Quality: Correct alignment ensures that the stylus follows the groove exactly as intended, delivering the intended stereo image and frequency response.

- Record Longevity: Misalignment can cause uneven wear on your records, reducing their lifespan. Proper alignment minimizes wear by distributing the stylus pressure evenly across the groove walls.

To align your stylus, you’ll need to adjust parameters such as overhang and azimuth to the manufacturer’s specifications. Tools such as alignment protractors can assist you with this process.

Alignment Techniques

Proper alignment of your stylus is critical for maintaining the fidelity of your audio playback and extending the life of your vinyl records. Accurate alignment minimizes tracking errors and distortion, ensuring that you get the best possible sound from your turntable setup.

Overhang Adjustment

To attain the proper overhang, position the stylus accurately to track the record groove. Start by situating the cartridge at a specified distance from the spindle, adhering to the turntable manufacturer’s guidelines or utilizing an overhang gauge. This ensures that the cartridge traces the optimal arc on the record, enhancing sound quality and reducing wear.

Cartridge Alignment Protractors

Utilize a cartridge alignment protractor to precisely align the cartridge in the headshell. A protractor helps to fix the cartridge at the correct angle, aligning it with the two null points-locations on the record where the stylus simultaneously tracks perfectly tangent to the groove.

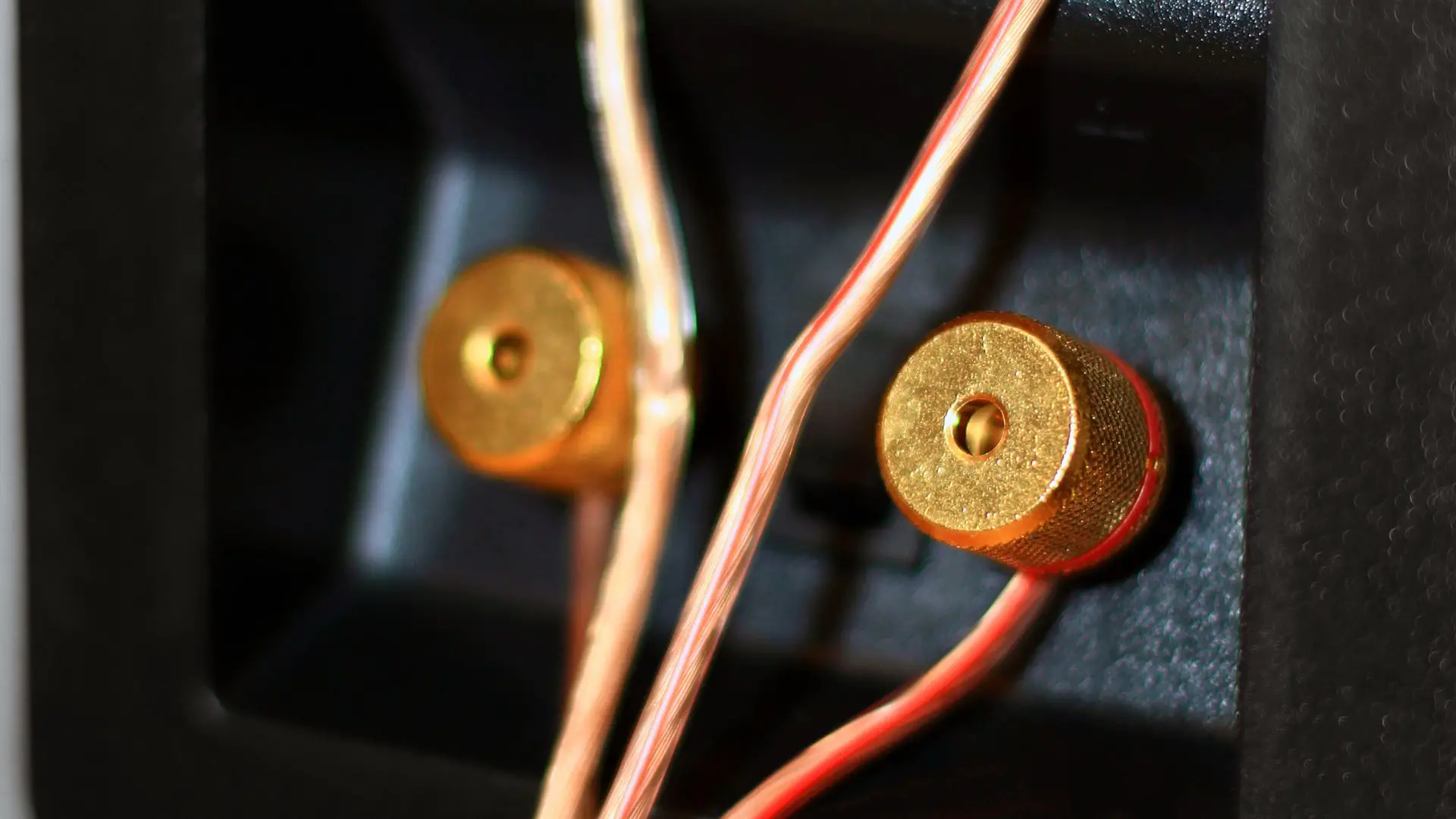

Setting the Azimuth

The azimuth refers to the vertical tilt of the stylus when viewed from the front of the turntable, the stylus should appear perfectly vertical and not leaning to either side. Precise azimuth setting is essential for achieving balanced channel separation and accurate sound reproduction. This can be adjusted on the tonearm and verified through the use of specialized test records or meters designed to aid in this aspect of cartridge setup.

Vertical Tracking Angle (VTA) Setting

The VTA is the angle at which the stylus meets the record groove. It is essential for optimal tracking and sound quality. You can adjust the VTA by raising or lowering the tonearm base, ensuring that the tonearm is parallel to the record surface when the stylus is in the groove. The proper setup of the VTA can influence the overall tonality and clarity of the music.

Optimizing Stylus Performance

To achieve the best audio quality and ensure the longevity of your vinyl records, precise stylus alignment is critical. This involves proper tracking force, anti-skating adjustment, and fine-tuning for audio fidelity.

Tracking Force Adjustment

Adjusting the tracking force is essential for optimal stylus performance. Place the correct amount of weight on the stylus to ensure it tracks the grooves accurately without causing excessive wear. Each cartridge has a recommended tracking force range (See your stylus manufacturer for more info), typically measured in grams. Use a reliable tracking force gauge to set this force accurately.

Anti-Skating Adjustment

Anti-skating prevents the stylus from being pulled towards the center of the record, ensuring even wear and consistent sound quality. For balance, the anti-skating force should match the tracking force. Turntables come with an anti-skating mechanism that you can adjust according to the manufacturer’s instructions, which generally involves setting a dial to correspond with the tracking force.

Fine-Tuning Audio Fidelity

Fine-tuning audio fidelity is about making minor adjustments to achieve the highest sound quality. After setting the tracking force and anti-skating, listen to a well-known record and make slight adjustments. Look for clear mid-range, crisp high frequencies, and well-defined bass. The correct alignment will minimize distortion and surface noise, providing a pure listening experience.

Preserving Your Vinyl Records

Ensuring optimal playback and extending the life of your vinyl records hinges on proper stylus alignment and maintenance strategies.

Reduction of Wear and Tear

To minimize wear and tear on your records, it’s essential to check the alignment of your turntable’s cartridge. A properly aligned stylus follows the grooves of your vinyl records precisely. This accuracy is crucial as it prevents the dragging or chipping of the groove walls which can result from a misaligned stylus ensuring that each play sounds as intended and reducing the rate of degradation.

The Role of Cleaning in Preservation

Apart from taking care of the stylus, consistent and meticulous cleaning is crucial for preserving your vinyl records. Dust and debris particles can embed themselves in the grooves, leading to stylus mis-tracking and potential damage to the delicate vinyl material. Employing a microfiber cloth and a specialized cleaning solution to clean your records can ensure a pristine surface, optimize sound quality, and uphold the integrity of your collection over the years.

When you encounter alignment problems with your turntable’s stylus, the quality of audio playback can be affected, and your records may suffer damage over time. Here are steps you can take to troubleshoot and correct these issues:

1. Check Cartridge Alignment: Start by ensuring that your cartridge is properly aligned. Use a cartridge alignment protractor to guide you. If the stylus isn’t following the grooves precisely, adjust the cartridge until the protractor’s grid lines and the cartridge body are parallel.

2. Inspect Stylus Condition: A worn or damaged stylus can cause misalignment. Examine it closely; if it’s bent or the tip is damaged, it needs replacing.

3. Balance the Tonearm: Incorrect tonearm balance can lead to tracking issues. Calibrate the tonearm’s counterweight to set the proper tracking force as recommended by the cartridge manufacturer.

| Step | Action to Take | Tool(s) Needed |

|---|---|---|

| 1 | Align Cartridge | Cartridge Alignment Protractor |

| 2 | Inspect Stylus | Magnifying Glass |

| 3 | Balance Tonearm | Tracking Force Gauge |

Advancements in Stylus Technology

Stylus technology has seen significant improvements, addressing both the accuracy of alignment and the ease of use for turntable enthusiasts and professionals. These advancements enhance your listening experience and ensure the longevity of your vinyl records.

Digital Stylus Gauges

Digital Stylus Gauges have revolutionized the way you calibrate turntable stylus force pressure. Precision is key, and these tools offer it, often with accuracy to within 0.01 grams. This level of detail ensures the stylus exerts the correct force, preventing damage to your records and stylus due to excessive weight. Moreover, digital gauges are user-friendly with clear electronic displays, you can adjust and set the optimal stylus pressure for your setup quickly and reliably.

Example of a Digital Stylus Gauge Readout:

- Displayed Weight: 1.75g

- Accuracy: ±0.01g

- Battery Life: 20 hours of continuous use

Conclusion

Your turntable’s performance greatly hinges on the precision with which your stylus aligns. Proper alignment is key for two principal reasons:

Sound Quality: A well-aligned stylus will faithfully trace the grooves of your vinyl, resulting in clearer and more accurate sound reproduction. As mentioned correct contact between the needle and record surface is fundamental for sound quality.

Preservation: Ensuring the stylus sits correctly protects both the needle and your records from undue wear. A stylus’s precision directly impacts the longevity of your audio components.

- To achieve this alignment, tools like a cartridge alignment protractor are required.

- Alignment also involves adjusting the overhang to maintain the stylus’s tangent position with the grooves across the record’s surface.

Remember, vigilant stylus care is not a one-time event but an ongoing aspect of turntable maintenance.